Objective

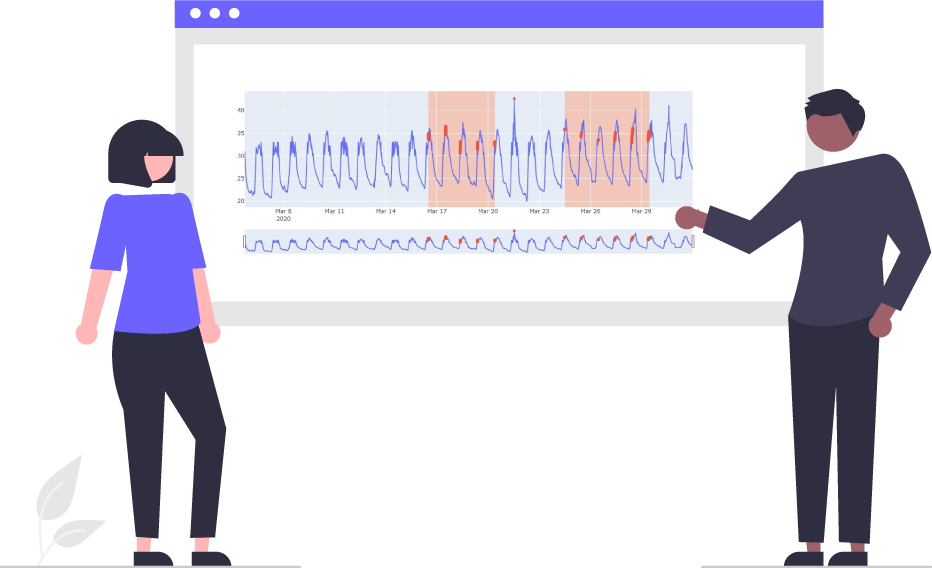

To provide a system that can alert any anomalous behavior in the sensor. Use past data and anomalous behaviors to identify potential future failures and degradation in the system.

Challenge

Sudden disruptions of the systems can result in extended periods of blocked production. Preventive maintainence is the best way to prevent such scenario. Systems show sign of failures earlier in the cycle, these come out as anomalous behaviors in the tracked metrics.

Solution

An AI based anomaly detction and preventive maintainence approach will result in more accurate anamoly detection. This coupled with the system parameters, can be used to effectively predict the time line of a failure and hence help in keep the production on all the time.

Contact us

GizaGlobal is your trusted partner for Industrial IOT and Digital transformation solutions